| [unchecked revision] | [unchecked revision] |

(Mise à jour pour être en accord avec la nouvelle version de la source de la page) |

(Mise à jour pour être en accord avec la nouvelle version de la source de la page) |

||

| Line 17: | Line 17: | ||

|ItemList={{ItemList | |ItemList={{ItemList | ||

|Item=Fusion splicer | |Item=Fusion splicer | ||

| + | }}{{ItemList | ||

| + | |Item=Clipper | ||

| + | }}{{ItemList | ||

| + | |Item=Isopropyl alcohol | ||

}} | }} | ||

}} | }} | ||

Latest revision as of 15:28, 7 June 2019

Contents

- 1 Items

- 2 Step 1 - Preparation of the accessories

- 3 Step 2 - Stripping and cleaning the fibre

- 4 Step 3 - Cleavage of the fibre

- 5 Step 4 - Positioning the fibre in the welder

- 6 Step 5 - Choosing the programs of the welder machine

- 7 Step 6 - Welding process

- 8 Step 7 - Welding evaluation

- 9 Step 8 - Positioning the smoove and shrinkage

- 10 Step 9 - Positioning the smoove on a cassette for winding

- 11 Comments

- Items

Items

Step 1 - Preparation of the accessories

Tools required: fusion splicer, clipper, stripper, lint-free wipes, isopropyl alcohol and heat-shrinkable splice guards (smooves).

Step 2 - Stripping and cleaning the fibre

Strip 3/4 cm of the fibre. Clean the bare fibre with isopropyl alcohol before cleaving.

NB: do not touch the fibre with your fingers once it has been cleaned.

Step 3 - Cleavage of the fibre

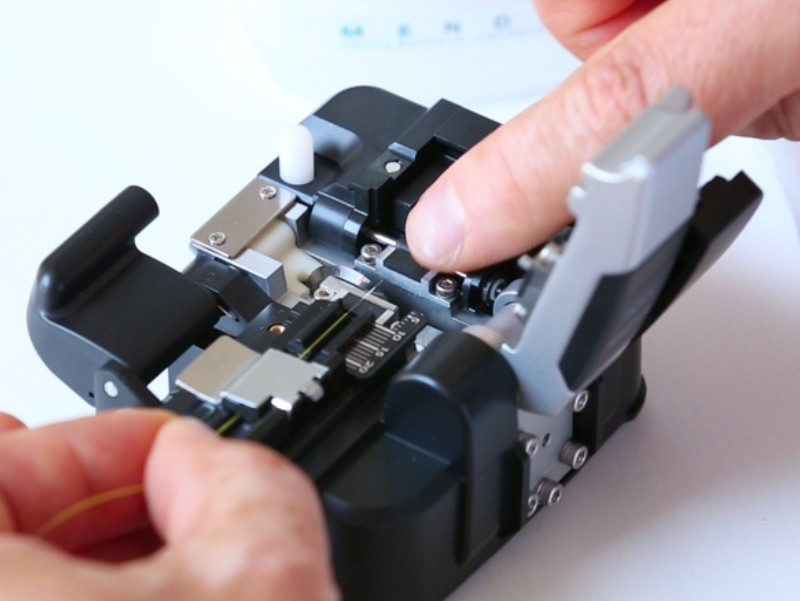

Position the fibre in the appropriate slot of the fibre guide (250 or 900 µm), the sheath 250 or 900 µm at scale 10, making sure that the devoid part rests firmly on the 2 pads.

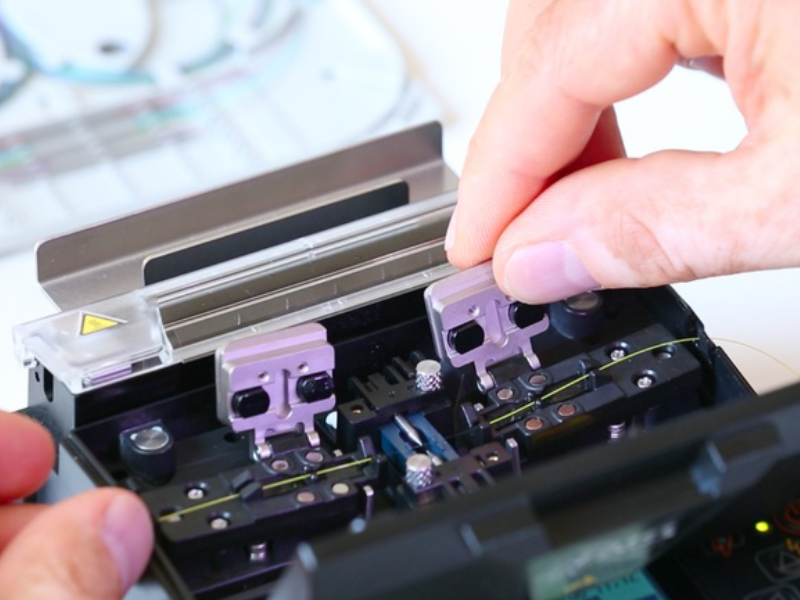

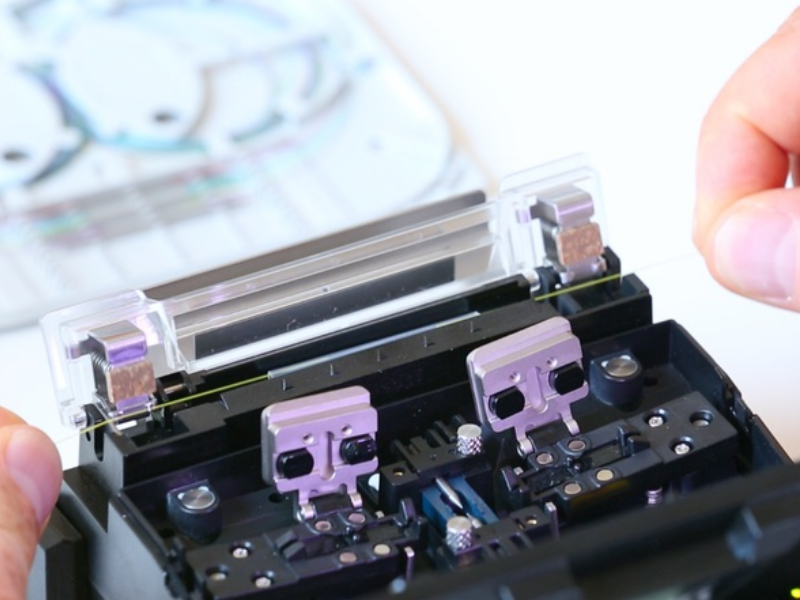

Step 4 - Positioning the fibre in the welder

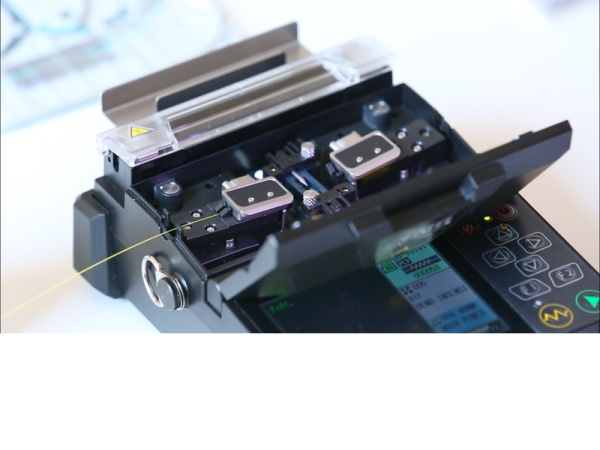

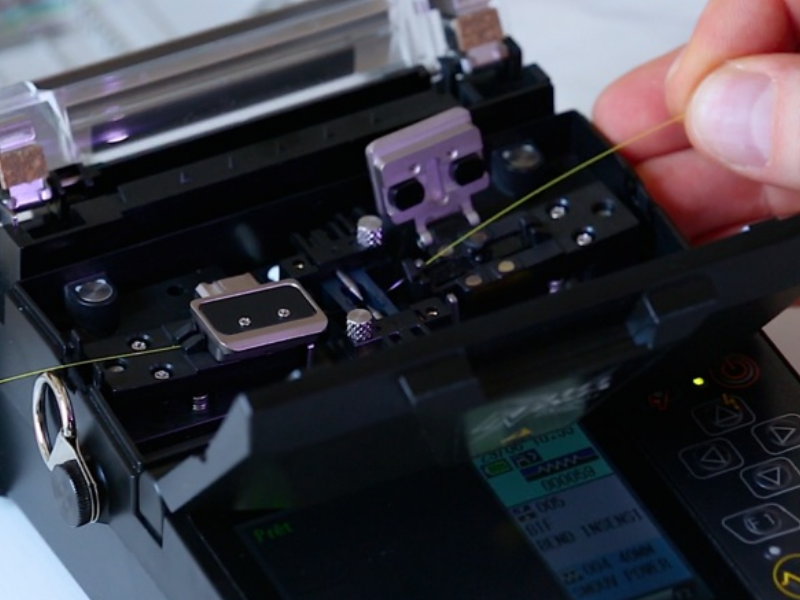

Position the fibre in the fusion splicer by placing its end between the alignment of the electrodes and the edge of the V-slot, close the valve retaining the fibre.

NB: Be careful not to hit the end of the fibre as this may alter the quality of the cleavage.

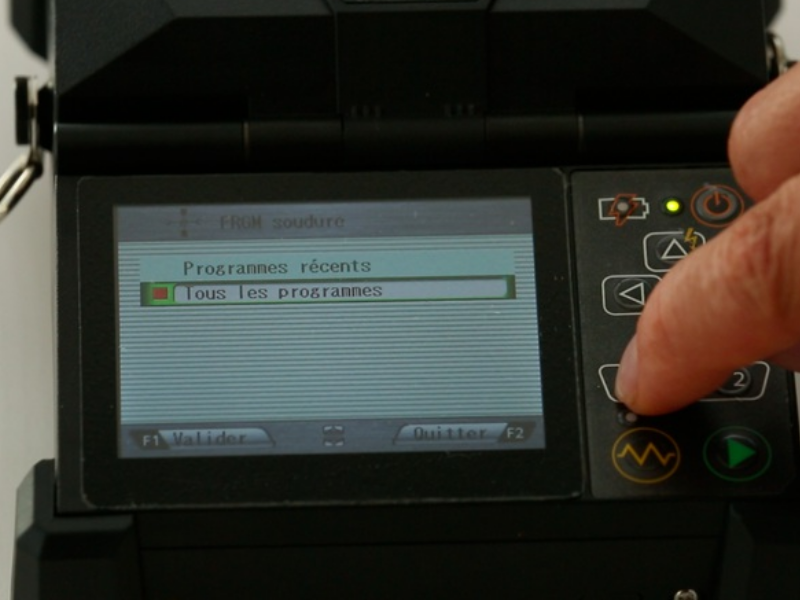

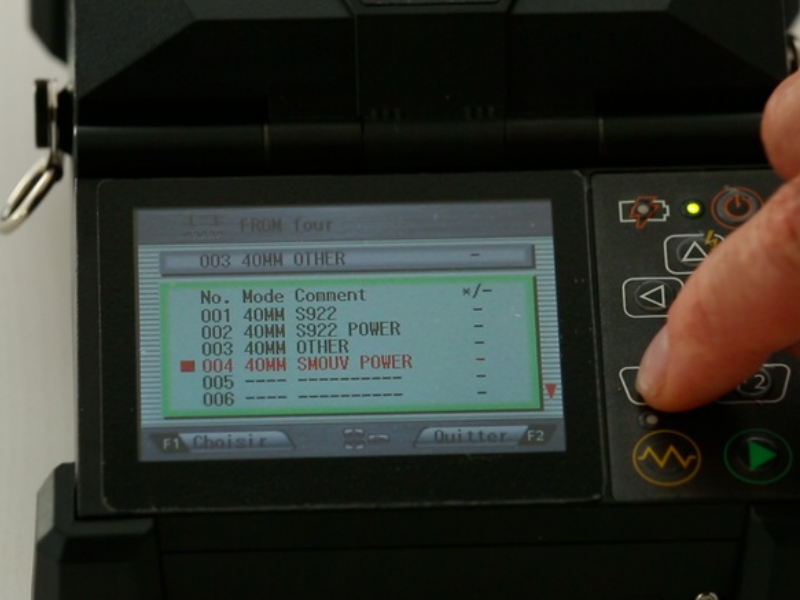

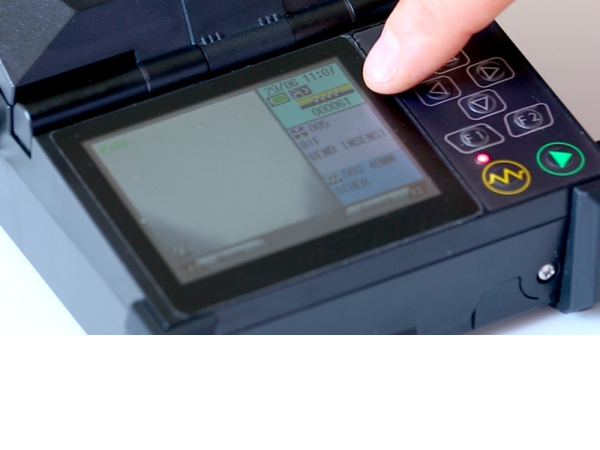

Step 5 - Choosing the programs of the welder machine

Use the welding program adapted to the type of fibre to be welded, as well as the furnace program adapted to the type of smoove used.

Example: Single mode MS, multi-mode MM and single mode BIF G657.

Step 6 - Welding process

Close the cover to initiate the welding process (the auto start function must be activated otherwise press the green arrow on the keyboard).

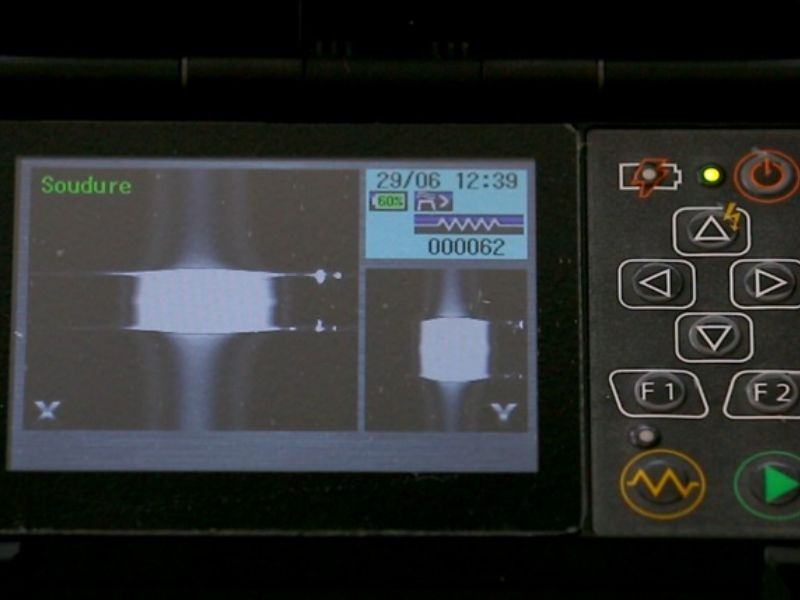

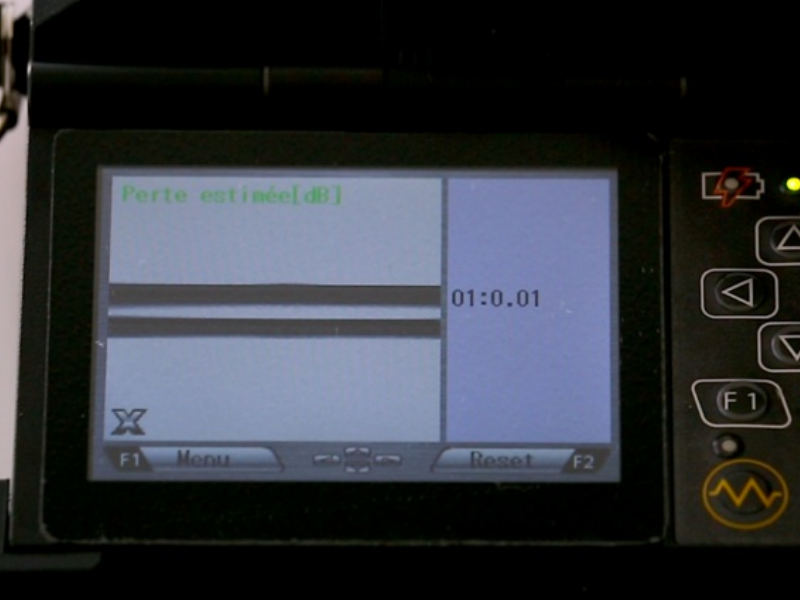

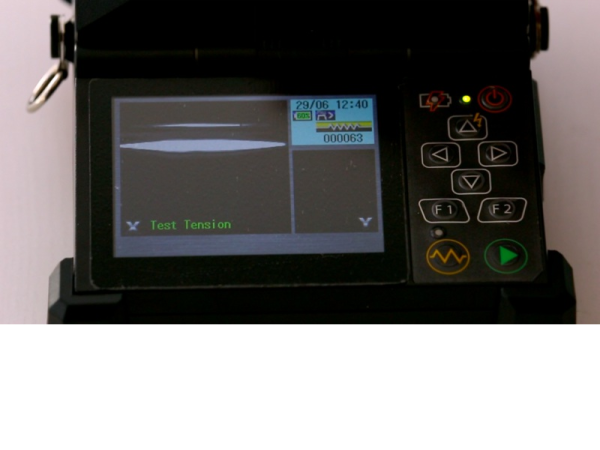

Step 7 - Welding evaluation

Three evaluation criteria should be observed: the image quality of the welded fibres (good alignment of the cores, absence of dust or air bubbles, etc.), the estimated loss given by the fusion splicer and the resistance of the fibre to the tensile test (not to be disabled).

Step 8 - Positioning the smoove and shrinkage

Before opening the cover, bring the smoove as close as possible to the fusion splicer, center it at the weld, making sure that the shrinkage will be on the fibre protection sheaths and not on the bare fibre. Position the smoove in the center of the furnace. The furnace is activated automatically if this function has been previously selected in the machine parameters, otherwise press the yellow resistance on the keyboard.

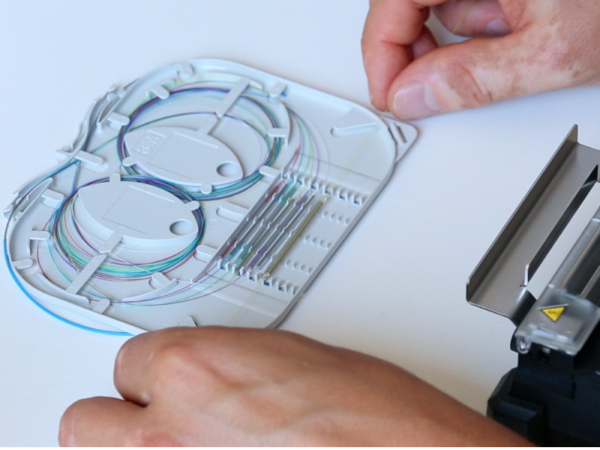

Step 9 - Positioning the smoove on a cassette for winding

After shrinking, position the smoove on the cooling plate before welding other fibres. Then place the smooves in the cassette and wind the fibres.

Published

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português