- Items

Items

Step 1 - Safety rule

The visual defect locator (or optical pencil) emits red light at an output power of 10 mW. Do not directly look at the light beam or direct it at another person. Always replace the protective cap after use.

Switch on the unit only when the protective cap is in place or a connector is attached to the outlet.

Step 2 - Ignition and configuration

Press the PWR button. The locator emits a continuous or pulsed signal depending on the setting selected with the MOD button.

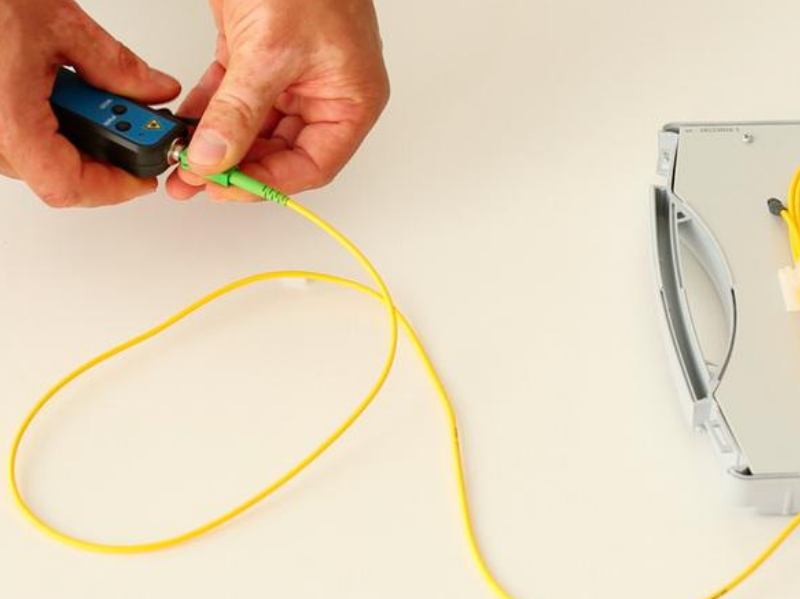

Step 3 - Connection to the fibre

The visual defect locator is compatible with all connectors with a 2.5 mm ferrule. For 1.25 mm ferrules, the use of an adapter is required.

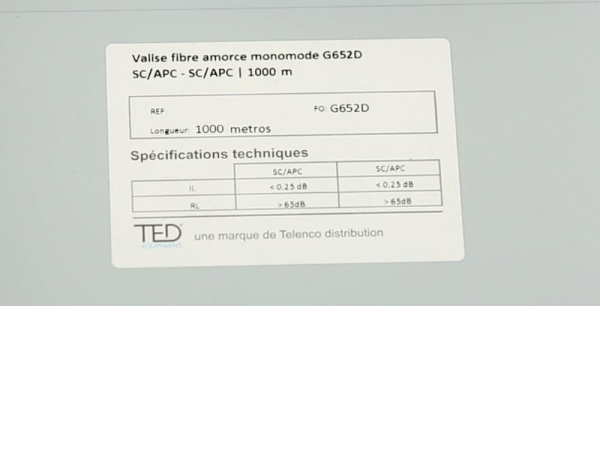

Step 4 - Identify the length of the fibre

The locator can be used on links up to 10 km. Beyond that, whatever the power of an optical pencil, the light beam cannot be perceived.

Step 5 - Locating the end

The end of an optical link is detected by the presence of the light signal. This is a function widely used for mixing garters in street cabinets or bays.

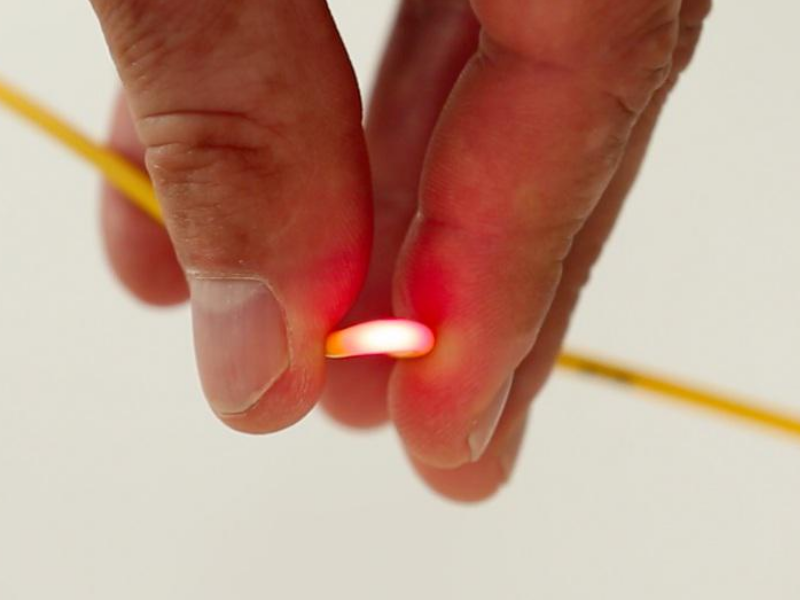

Step 6 - Locating the defect (a curve for example)

Due to the high reflection of the light as it passes through a stress (macro-curve) or when a fibre is cut, this device is widely used to correct defects (which cause significant optical losses), on the visible part of the fibres.

Step 7 - Turn off the device

After using the device, turn off the locator and place the protective cap on the optical output.

Published

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português